Industrial Welding Robot Manufacturers in Maharashtra

Industrial Welding Robot Manufacturers, Suppliers in Maharashtra

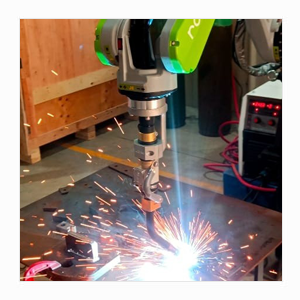

Inatoz Robotics automation Pvt. Ltd. is a Superb Industrial Welding Robot manufacturers, Suppliers and Exporters in Maharashtra. An Industrial Welding Robot is defined as a machine that does the work in an automated fashion to weld accurately, effectively, and repetitively.

Know about Industrial Welding Robot

Industrial Welding Robots Are Usually used to perform welding. Their configurations include robotic arms with sensors and sophisticated programming techniques since these robotic machines are capable of executing several welding processes, such as arc welding, spot welding, or laser welding. This system uses artificial intelligence and machine learning to compensate for any error under the actual welding conditions.

Types of Industrial Welding Robots Which We Offer:

As a trusted manufacturers and suppliers of Industrial Welding Robots in Maharashtra, we provide advanced robotic solutions tailored to diverse industrial needs.

- Cobot Welding Robots: These robots are built to work shoulder to shoulder with a human operator. They have safety features and AI-controlled systems to provide flexibility, reduced setup time, and efficiency, especially in small-scale custom arenas.

- Adaptive Welding Robots: These types of robots use their capability of AI and machine learning to analyse their data in real-time.

- Rotational Welding Robots: These are applicable for welding cylindrical and irregular-shaped workpieces, such as pipes and pressure vessels.

- Friction Stir Welding Robots: This is a well-established solution for welding lightweight metals, such as aluminium, using friction heat instead of melting. It is capable of producing defect-free, high-strength welds required in applications relating to aerospace, railways, and EV battery enclosures.

- Remote-Control Welding Robots: With advanced sensors and cameras with wireless technology, the welding processes can be executed remotely.

Technical Specifications of Industrial Welding Robot

A leading manufacturers and exporters of industrial welding robots in the state of Maharashtra, our advanced welding robots have a multitude of technical specifications, tailor-made to suit the unique requirements of different industries.

Specification | Cobot Welding Robots | Adaptive Welding Robots | Rotational Welding Robots | Friction Stir Welding Robots | Remote-Controlled Welding Robots |

Voltage | 220 V | 220 V | 220 V | 220 V | 220 V |

Axis Configuration | 6axis or 7axis | 6axis with AI integration | Multiaxis for rotational movement | 3 to 5axis for linear movement | 6-axis robotic arms with remote control |

Payload Capacity | 3 kg 15 kg | 10 kg 100 kg | 10 kg 200 kg | 5 kg 50 kg | 5 kg 150 kg |

Reach Range | 500 mm 1800 mm | 700 mm 2500 mm | 1000 mm 3000 mm | 800 mm 2500 mm | 1000 mm 3500 mm |

Repeatability | 0.03 mm 0.1 mm | 0.02 mm 0.05 mm | 0.05 mm 0.1 mm | 0.02 mm 0.08 mm | 0.05 mm 015 m |

Welding Speed | 10 mms 150 mms | 10 mms 200 mms | 20 mms 250 mms | 5 mms 100 mms | 10 mms 180 mms |

Power Supply | 220V 380V, 50/60Hz | 220V 440V 50/60Hz | 380V 440V 50/60Hz | 220V 380V 50/60Hz | 220V 440V 5060Hz |

Welding Current | 50A 350A | 50A 600A adaptive | 100A 500A | N/A uses frictional heat | 50A 450A |

Compatible Materials | Steel, Aluminium, Stainless Steel | Steel, Aluminium, Copper, Titanium | Heavy Steel, Stainless Steel, Aluminium | Aluminium, Copper, Magnesium, Titanium | Steel, Stainless Steel, Special Alloys |

Features and Benefits of Using our Industrial Welding Robot:

As a premier suppliers and exporters of Industrial Welding Robots in Maharashtra, we specialize in delivering high-tech, precision-driven robotic with innovative features.

- Fixture Elimination: Modern robotic systems have evolved to perform their welding tasks with no need for fixtures, thereby streamlining operations and cutting down on setup time.

- Automated Sensing Methods: With the help of state-of-the-art sensor technologies, robots can adjust to any changes in the work piece to ensure constant quality of the weld, thus allowing for design modifications with very little downtime.

- Real-Time Data Acquisition and Analysis: Data on welding is fuelling robots for concurrent acquisition and analysis, prompt evaluation of the quality and optimization of processes, thus ensuring heavy throughput with little defective work.

- AI Integration: This is, after all, a great application for artificial intelligence if one is seeking to allow the welding robots to change their settings in real-time according to surface status to ensure the desired standard of weld quality.

- Advanced Welding Technology: Newer technologies, such as Buried Arc Welding, enable deep arc penetration in the weld pool and into the base material to achieve very high deposition rates and minimal defects compared to any other conventional welding processes.

Applications of our Industrial Welding Robot:

As a pioneering manufacturers and exporters of Industrial Welding Robots in Maharashtra, we engineer next-generation robotic solutions that revolutionize industrial welding.

- EV Manufacturing & Battery Welding: Maharashtra is gearing up to be an EV hub, welding robots have come into greater prominence for battery module assembly and lightweight chassis welding in highly precise and robust manufacturing of evs.

- Smart Factory Integration: High-speed welding robots as part of intelligent smart factories in Industry 4.0, powered by AI, facilitate real-time continuous monitoring, predictive maintenance, and adaptive modification in welding to optimize the whole productivity.

- Renewable Energy Equipment Fabrication: Industrial robots weld the frames of solar panels, wind turbines, and storage facilities for all energy needs that are being desperately needed to realize Maharashtra’s vision of a green energy future.

- Weld Aerospace and Defence Components: Today, robotic welding pursues precision-created components for aircraft and defence equipment more than ever before. Composing is the way superior quality and excellent consistency define the manufacture of high-strength parts.

- About Infrastructure and Metro Rail Projects: Automated welding robots provide rapid and reliable manufacturing of steel structures, together with bridges and metro rail components that complement large-scale infrastructure development in Maharashtra.

Why choose us?

Inatoz Robotics Automation Pvt. Ltd.is aiming to reinvent industrial welding robotics manufacturers, suppliers, and exporters in Maharashtra .We ensure top-quality and reliability through AI-driven automation, real-time monitoring, and top-notch welding technologies. We definitely keep on innovating to give industries the advantage of the next generation of welding automation towards a smart and efficient future.